Address

ICS Coating (M) Sdn Bhd No11, KWS IND PMTG2, 14000 BM, PENANG, MALAYSIA

Coating Technology Know-How

ICS offers advanced coating solutions using PVD, PACVD, and our proprietary SPLIT ARC Technology*. These methods deliver durable, high-performance coatings with excellent wear resistance, hardness, and low friction.

Our PVD process ensures smooth, uniform coatings, while PACVD enables low-temperature, 3D-compatible coatings like DLC and SiO₂.

DLC coatings are ideal for tribological systems, precision tools, aerospace, and medical applications thanks to their hardness, chemical stability, and biocompatibility.

From industrial tools to medical devices, our coating expertise enhances performance and extends product life.

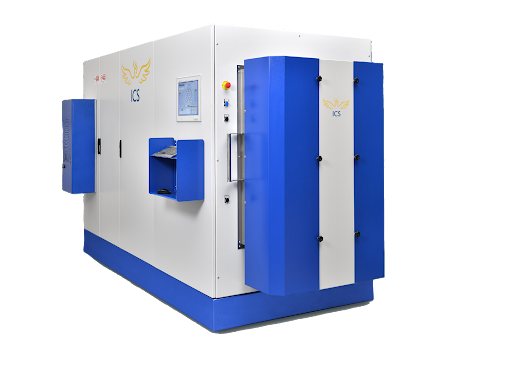

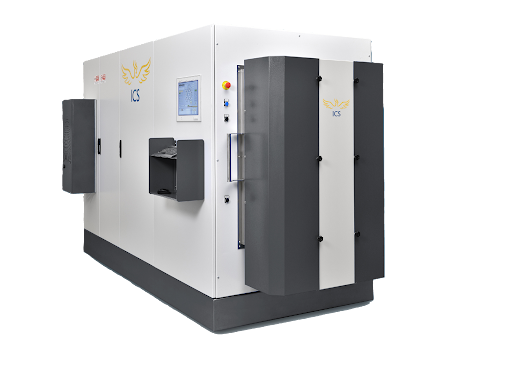

1. ICS PVD Coating Technology

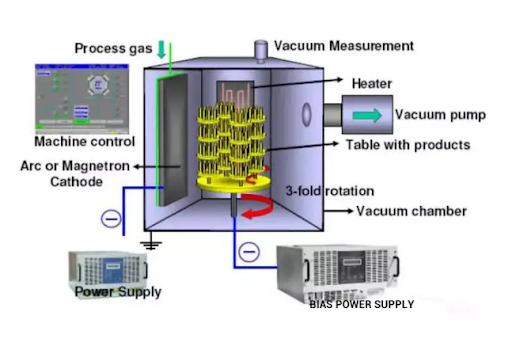

ICS specializes in Physical Vapor Deposition (PVD)—a process that forms strong, wear-resistant coatings by vaporizing metal and reacting it with gases to create a thin film.

Our process uses arc evaporation, where a high-energy arc vaporizes material from a metal target. Electromagnetic fields control the arc to ensure even coating and minimize defects. However, arc evaporation can produce droplets that reduce coating quality.

To solve this, we developed SPLIT ARC – TECHNOLOGY*: A “Plasma-Splited-Arc” system designed to reduce droplet formation, delivering smoother, denser, and high-performance coatings.

ICS applies PVD coatings using nitrides, carbides, and carbonitrides of Ti, Cr, Zr, as well as advanced alloys like AlCr, AlTi, and TiSi—ideal for tools and industrial components.

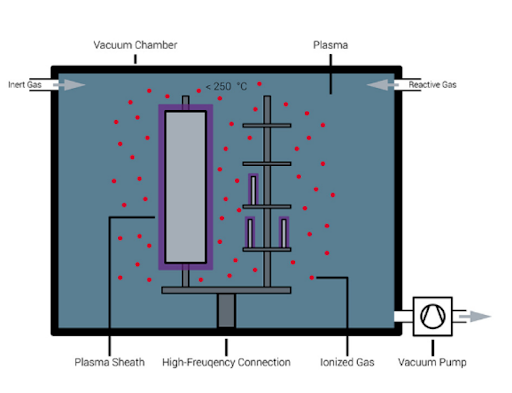

2. ICS PACVD Coating Technology

Plasma Assisted Chemical Vapor Deposition (PACVD) is a low-temperature (below 200 °C), vacuum-based process ideal for coating both conductive and non-conductive materials. It produces smooth, amorphous coatings—typically 2–3 µm thick—with high hardness (10–40 GPa) due to ~80% sp³ carbon bonding.

PACVD is widely used to deposit Diamond-Like Carbon (DLC) and SiO₂ coatings. Since all reactants are gaseous, it enables uniform coverage of complex 3D parts without rotation, unlike PVD.

3. DLC - The Ideal Solution for Tribological Systems

Diamond-Like Carbon (DLC) coatings—applied via PVD arc, sputtering, or PACVD—offer exceptional hardness, wear resistance, and low friction, even under dry or low-lubrication conditions.

Ideal for sliding and rolling systems like engines and machinery, DLC also suits high-precision tools, decorative items, and medical components due to its smooth finish, biocompatibility, and chemical inertness.

Benefits of DLC Coating:

- Broad range of substrate materials can be coated due to the low deposition temperatures

- No distortion of high precision substrates

- No post treatment necessary

- Gaseous process for uniform coating of 3D geometries without rotation

- Green technology with respect to educts, process and products

Common Applications:

- Engine wear parts and injectors

- Aluminum and non-ferrous metal cutting and forming process

- Industrial machinery components

- Plastic injection molding tools

- Aerospace components

- Medical instruments

- Semiconductor parts

- Watches and jewelry

- Hard chrome replacement

ICS 90 series

ICS 90 ADLC

Amorphous Diamond Like Carbon Coating

Application of ICS 90 coating on Automotive Fields:

We provide a smooth, corrosion-resistant, wear-resistant coating for components. Particularly in the automotive industry, energy conservation has become a trend in the development of the industry, we provide a wide range of coating for this applications space, less fuel consumption, less exhaust and maintenance more economical will be our goal.

ICS 91 series

ICS 91 DLC

Diamond Like Carbon Coating

Application of ICS 91 coating on Semiconductor Fields:

We provide smooth and low friction coating process for semiconductor trim and Form Parts, Auto Insert field and etc., not only extend the tool life of parts, but also improves product quality, surface finishing, reduced maintenance costs and will use less lubricant.

ICS 93 series

ICS 93 RAINBOW DLC

Non-Ferrous Metal Cutting

Application of ICS 93 coating on Cutting Non Ferrous Metal Fields:

We provide smooth and extreme low friction coating for non ferrous metals cutting process, not only extend the tool life of parts, but also improves product quality, surface finishing, reduced maintenance costs and will use less lubricant.

ICS 98 series

ICS 98 ESD DLC

Static Dissipative

Diamond Like Carbon Coating

Application of ICS 98 coating on Semiconductor Fields:

We provide ESD (Static Dissipative), smooth and low friction coating process for semiconductor components and carriers, not only to enhance the static electricity protection capability and dissipate static electricity for extend the tool life of parts, but also improves product quality, surface Finishing and reduced maintenance costs.