Address

ICS Coating (M) Sdn Bhd No11, KWS IND PMTG2, 14000 BM, PENANG, MALAYSIA

ICS GLOBAL TECHNOLOGY LTD

Why Choose ICS?

Industry Expertise

With over 25 years of experience, we deliver high-performance coating technologies for various industries.

Tailor-Made Solutions

We provide custom coatings for cutting, injection moulding, forming tools, and OEM parts to ensure top performance.

Customer Collaboration

We work closely with customers to ensure precision and satisfaction throughout the entire process.

Certified Quality Assurance

We are committed to maintaining top-tier standards, backed by certifications including ISO 9001, ISO 13485, TS 16949, and AS 9100.

Coating Technology Solutions

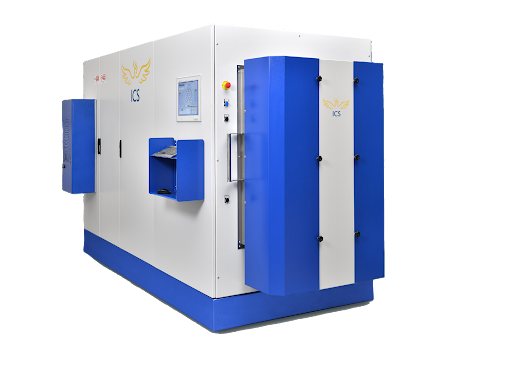

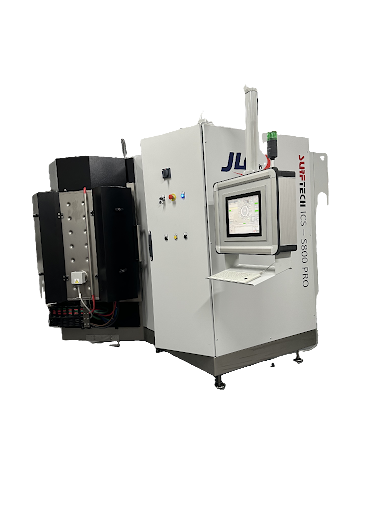

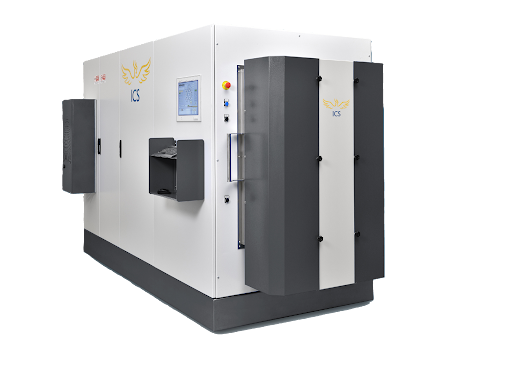

1. Physical Vapor Deposition (PVD)

ICS’s PVD technology uses metal vapor and selected gases to create durable, metal-based coatings that provide excellent strength and resilience, ideal for wear resistance and corrosion protection.

2. Plasma-Assisted Chemical Vapour Deposition (PACVD)

ICS’s PACVD technology applies plasma to deposit high-performance coatings at low temperatures, offering hardness, wear resistance, and versatility for a wide range of conductive and non-conductive materials.

3. Diamond-Like Carbon (DLC)

ICS’s DLC coatings provide exceptional hardness, wear resistance, and low friction, making them perfect for high-precision tools, engines, and medical implants, while also offering biocompatibility and corrosion resistance.

Application

Cutting Tools

Advanced PVD coatings that deliver exceptional wear resistance, longer tool life, and superior coating uniformity for high-performance machining.

Mold & Die

Protective coatings for stamping, plastic, and die casting molds, improving surface quality, extending mold life, and reducing downtime and lubrication needs.

Automotive Components

High-performance coatings that enhance durability and reduce friction, supporting fuel efficiency, lower emissions, and cost-effective maintenance.

Medical Devices

FDA-compliant biocompatible coatings designed to reduce glare, improve tool longevity, and minimize allergic reactions for safer medical use.

Semiconductor Components

Precision coatings with anti-static, low-friction, and non-stick properties, extending component life, improving product quality, and reducing maintenance.

Precision Coatings Designed for Your Industry Needs

Get in touch now to explore customized coating solutions that ensure your tools and parts meet the highest standards of durability and efficiency. Our experts are ready to create the perfect solution for your needs!

Frequently Asked Questions

Didn’t find what you’re looking for? Reach out to our customer service.

What does ICS COATING (M) SDN BHD specialize in?

What industries benefit from ICS’s coating technologies?

ICS serves a wide range of industries, including:

- Automotive (engine parts, injectors)

- Aerospace

- Medical (instruments, implants)

- Tooling (cutting, forming, injection molding)

- Electronics and semiconductors

- Watch and jewelry manufacturing

- General industrial machinery

What is the difference between PVD, PACVD, and DLC coatings?

- PVD uses metal vapor and gases to form hard, wear-resistant coatings, ideal for tools and components.

- PACVD is a low-temperature, gas-based process that allows uniform coating of complex 3D shapes.

- DLC coatings, which can be deposited via both PVD and PACVD, provide extreme hardness, low friction, and chemical inertness—ideal for high-performance and medical applications.

Does ICS offer customized coating solutions?

Yes. ICS provides tailored coating solutions based on customer requirements, material types, and application needs. From selecting the right coating composition to optimizing deposition parameters, ICS ensures the best performance for each specific use case.

Where are ICS’s services available in Asia?

What quality certifications does ICS hold?

ICS is committed to high-quality standards and holds internationally recognized ISO certifications, ensuring consistent quality, safety, and reliability in every coating process.